FAQ

Skip to: General FAQ | Sonic Sifter FAQ | DuraTap FAQ

General FAQ

What are your products used for?

Sieving is the simplest, quickest and most economical means of particle size distribution analysis. Whether in food, pharma, foundry or cement and aggregate, your raw material particle size is critical to the quality and performance of your finished product.

What is CENTERLINE® sieve certification?

Which sieve shaker is best for my needs?

Advantech Mfg. has three sieve shakers to offer; each with very different action on the particle.

- If gentle, efficient, small sample size sifting is what you need, the Advantech Mfg. L3P Sonic Sifter or VariSifter is a perfect fit. Our Sonic Sifting line utilizes 3” diameter sieves in mesh sizes 5.6mm down to 3um. The oscillating sonic wave provides shorter test times with little particle attrition. The vertical and horizontal tapping* helps to redistribute particles on the sieve surface and break up agglomerates.

- The Advantech Mfg. DuraTap™ is a rugged, oscillating and tapping shaker suitable for 8” (or 200mm) and 12” (or 300mm) diameter testing sieves. Our DuraTap™ is an excellent solution for larger sample sizes where more vigorous shaking and vertical tapping is required for your sample.

- Does your testing procedure call for vibratory sifting or the ability to be mobile? Then our Meinzer II is the answer. The Meinzer II is a small, portable, tabletop sifter which accommodates 8” or 200mm testing sieves. This model is especially effective with larger particle sizes.

*Horizontal tapping is produced by our L3-N8 Horizontal Pulse Accessory unit, which is a separate optional purchase. The VariSifter has horizontal tappers built into the machine.

How can I submit a Purchase Order (P.O.) or request and RFQ?

You can send a Request For Quote (RFQ) or place an order via email by sending a P.O. to sales@advantechmfg.com or by calling us at 262-786-1600 Monday through Thursday 8 A.M to 4 P.M. (Central).

I just need a quote, can I do that online?

YES! If you would like to get a quote, you can shop as usual on this site and simply select "Quote only" as the payment method when checking out. Once your request is submitted, a customer service representative will provide you with a formal quotation via email.

I need an invoice before I can place an order, can i do that online?

YES! If you would like an invoice, you can shop as usual on this site and simply select "Invoice" as the payment method when checking out. Once your request is submitted, a customer service representative will provide you with a invoice via email.

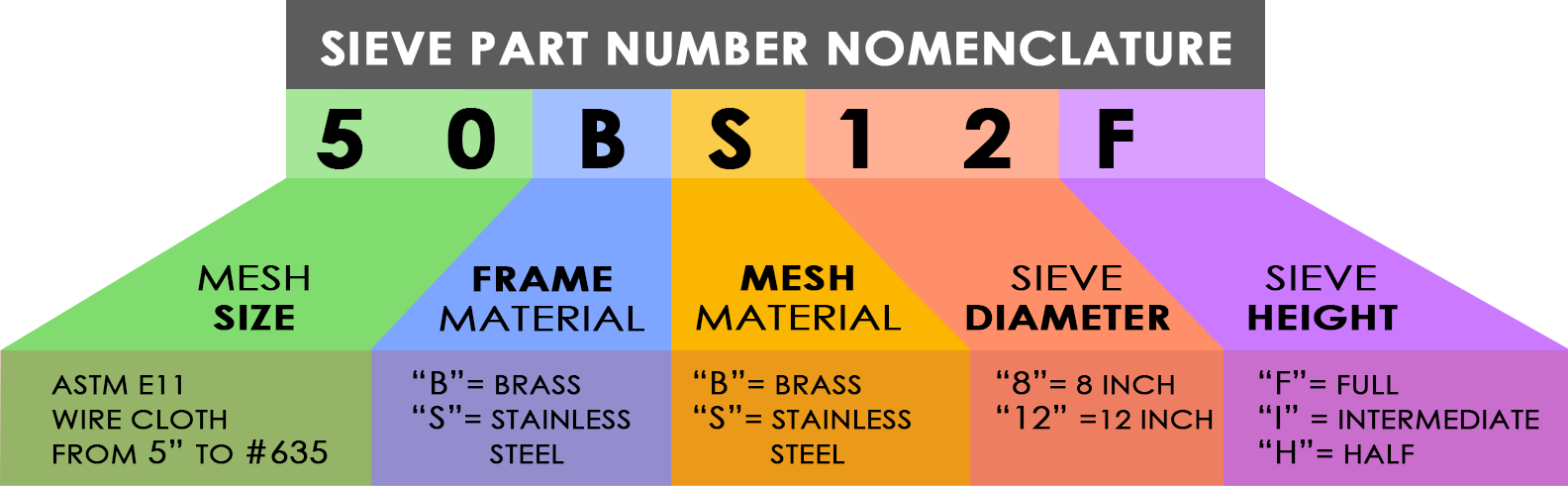

How do I "read" your part number?

Our online store allows you to select your sieves either step-by-step (example here) or you can order by part number here.

Where do I find a product manual or get help?

For help, you can always call us at 262-786-1600 or download the manual from our resources page.

Where can I find the ASTM E11 Standards?

You can download the ASTM standards table here: ASTM E11-15 Standards Table

Sonic Sifter Separator FAQ

For specific sieving procedures, please refer to Test Sieving: Principles and Procedures located in the User’s Manual.

Can I use one sieve and fill the rest of the stack with spacers?

Yes, a single sieve can be used at a time. Be sure to add spacers at the top of the stack and place the sieve at the bottom. Please note when using precision mesh sieves, only one sieve may be used at a time while performing separations of 30 microns and finer.

When would I need a Horizontal Pulse Accessory (L3-N8)

While sifting media 45 microns and finer, it may be beneficial to incorporate the L3-N8 Horizontal Pulse Accessory. This accessory replaces one of the standard spacers and adds a horizontal tap from alternate sides of the sieve stack, aiding in elimination of particle agglomeration. It may also help with the effects of electrostatic charge.

How do I determine the best amplitude setting for my test?

Always start the test at zero amplitude. Slowly increase the amplitude until the heaviest particles are rolling on the sieve surface. Media particles should arc no higher than half the height of a standard sieve therefore never touching the sieve above it. When using precision mesh sieves, media particles should arc a maximum of ¼” above the wire mesh surface. Final test results may be adversely affected by not complying with this rule.

How long should I run my test?

Generally, there are industry or “in-house” standards for sieving duration. For instructions on determining the optimum test time, please refer to the Recommended Time Intervals section in Chapter 6: Performing the Sieve Analysis in the Test Sieving: Principles and Procedures manual. Generally, with the L3P Sonic Sifter, the test is complete when media is no longer filtering into the next sieve. It is recommended to perform three tests for repeatability, noting the amplitude setting and test time for the running of future tests.

The media samples are not staying within the stack assembly. What is happening?

There are a few possible reasons for the sample escaping the stack assembly:

- The stack may have been improperly assembled and inserted.

- There may be holes or tears in the fines collector or diaphragm or cracks in the sieve frames.

- The amplitude may be improperly set.

Start by examining the sieve stack assembly. Be sure the following steps have been executed:

- Hook Fines Collector to bottom of Fines Collector Holder.

- Assemble your sieve stack with up to six standard sieves or up to three precision mesh sieves. If fewer sieves are used, replace with Spacers.

- Add the Top Cone.

- Add the sample.

- Add the Diaphragm.

- Add the Column Lock and snap the arms down under the rim of the Fines Collector Holder.

- Insert the stack assembly into the test chamber until it hits the stop at the rear and the table switch is fully engaged.

- Release both arms on the column lock. A firm snapping sound will be heard.

- Your sieve stack should fit very securely in the test chamber.

If this has not solved the problem, visually inspect the Diaphragm and Fines Collector for holes or tears and each sieve frame for cracks. Examine the Column Lock springs. There should be six springs, all oriented vertically.

Lastly, setting the amplitude too high may also contribute to loss of the sample. Refer to question three for instructions on setting the amplitude.

My L3P Sonic Sifter does not turn on or will run for a short time, then stop? What is happening?

The stack assembly must be fully inserted into the test chamber and locked in place by releasing the Column Lock arms. Please refer to question five for instructions on properly assembling and inserting the sieve stack assembly. If the column lock is not released, the stack is able to vibrate out of position, releasing the table switch and turning the unit off. The table switch must remain fully engaged in order for the unit to function.

Can the L3P Sonic Sifter be operated with the door open?

Yes. However, it is not recommended the door be wide open as it may alter your test results. When using the L3-N8 Horizontal Pulse Accessory, however, it is necessary to leave the door open just enough to allow the cord to pass under the door.

Why does the L3P Sonic Sifter have a light inside?

The light allows the user the ability to set the proper amplitude. The sieves were designed with clear acrylic frames so sample media can be viewed while the test is running. The appropriate amplitude has been achieved when the largest particles of the sample are observed rolling on the sieve surface and none arc higher than half the height of the sieve frame. Particles that are arcing too high will be forced back into the sieve above, thereby altering the test results.

Does the L3P Sonic Sifter have to be calibrated?

No. The L3P Sonic Sifter does not come calibrated. If the user wishes to establish defined testing levels, it is recommended a decibel meter be purchased to aid in determining precise unit settings. The sonic wave pulse rate is basically controlled by the line voltage hertz. Amplitude merely controls the volume of the sound wave rather than the timing. Test sieves, however, can be certified using Advantech’s Centerline Sieve Certification.

Does Advantech calibrate/certify test sieves for the L3P Sonic Sifter?

Yes. Test sieves can be certified using Advantech’s Centerline Sieve Certification. Please see the answer to question nine for specifics on the varied levels of certification service Advantech offers. For a suggested re-certification schedule, please contact our Customer Service Team at 262-786-1600 or sales@advantechmfg.com.

What is the warranty on the L3P Sonic Sifter?

The L3P Sonic Sifter carries a one year limited warranty against defective material and workmanship.

Can I use 3” brass sieves in my L3P Sonic Sifter?

No. The L3P Sonic Sifter is designed only for use with 3” acrylic sieves and the diaphragm and fines collector. Metal 3” sieves are not compatible.

Does the L3-N8 Horizontal Pulse Accessory come in a 220 volt model?

No. However, a P6835 Step-Down Transformer may be purchased. This will convert 220 volt input to a 110 volt output which will then be compatible with the L3-N8 Horizontal Pulse Accessory.

Does Advantech have a repair facility nearby?

Advantech is pleased to offer telephone repair support for the L3P Sonic Sifter. Contact a member of our Tech Support Team at 262-786-1600. Alternatively, machines may be sent in to our location in New Berlin, WI for extensive repair or refurbishing. Contact us for information on how to prepare your machine for receipt and service by our Repair Department.

DuraTap Sieve Shaker FAQ

For specific sieving procedures, please refer to Test Sieving: Principles and Procedures located in the User’s Manual. For added reference, a DuraTap Parts Diagram is located in the front portion of the User’s Manual.

What is the oscillation displacement on the DuraTap and how many oscillations and taps per minute does the DuraTap produce?

The DuraTap’s oscillation displacement is 1-1/8” x ¾”. The oscillations and taps per minute will be dictated by the model DuraTap you have. Please see the chart below for approximate oscillations and taps per model.

| Model | Voltage | Hertz | *OPM | *TPM |

| DT158 | 110 | 50 | 267 | 150 |

| DT168 | 110 | 60 | 278 | 154 |

| DT258 | 220 | 50 | 268 | 154 |

| DT268 | 220 | 60 | 278 | 152 |

| DT1612 | 110 | 60 | 278 | 154 |

| DT2612 | 220 | 60 | 278 | 152 |

| DT2512 | 220 | 50 | 268 | 154 |

*These are approximate oscillations and taps per minute.

What sort of maintenance is required for the DuraTap?

The DuraTap for the most part just needs to be kept clean. There are two grease fittings on the DuraTap which require service after every five hours of operation. (Please refer to the DuraTap Parts Diagram in the front portion of the User’s Manual.) One port is on top of the unit in the BA106/BA119 Yoke (30/30a). This fitting feeds the DA211 Eccentric (5) housed in the BA102/BA120 Yoke (30/30a). The second port is on the lower rear part of the BA101 Tower & Base Assembly (45). This fitting feeds the DA211 Eccentric (5) housed by the DA201 Lower Carriage Plate (21). The BA105 Stationary Block (48) should also be periodically greased. A Moly EP (extreme pressure) multi-purpose grease is recommended.

Does the DuraTap have to be calibrated?

The DuraTap is not a calibrated machine. The taps and oscillations can be verified to make sure the machine is still operating at manufacturer’s specification. (Please refer to Chart 1A). The oscillations and taps per minute are basically a product of motor rpm, line-in voltage and the hertz of that voltage. Test sieves, however, can be certified using Advantech’s Centerline Sieve Certification.

Does Advantech calibrate/certify test sieves for the DuraTap?

Yes. Test sieves can be certified using Advantech’s Centerline© Premium Sieve Certification. Please see the answer to question three for specifics on the varied levels of certification service Advantech offers. See the suggested re-certification schedule.

How many sieves can I fit in my DuraTap?

Please refer to the chart below for details on the DuraTap’s sieve capacity. Fewer sieves may be used by loosening the nuts and adjusting the height of the BA132/BA122 Sieve Support Clamp Assembly (36/36a) to the level necessary to securely hold the sieve stack.

| Half Height | Intermediate Height | Full Height | Pan | Cover | |

| 8” or 203.1mm | 13 | N/A | 6 | 1 | 1 |

| 12" or 304.8mm | 7 | 6 | 3 | 1 | 1 |

My DuraTap is making a lot of noise and the sieve stack seems unstable in the machine. What is wrong?

The sieve stack may have been improperly constructed and inserted.

- Start the sieve stack with the pan at the very bottom.

- Load the sieves on top of the pan. An extended rim pan may be inserted within the stack to run multiple samples. Bear in mind the overall height of the sieve stack may not exceed the capacities as shown in the above chart.

- Introduce the sample and place the BA106/BA119 DuraTap Sieve Cover (30/30a) on top of the sieve stack as shown in Figure 6A. Figure 6B illustrates an improperly installed Figure 6A DuraTap Sieve Cover.

- Place the sieve stack onto the BA132/BA122 Sieve Support Clamp Assembly (36/36a)

- Adjust the BA132/BA122 Sieve Support Clamp Assembly (36/36a) up far enough that the sieves will be securely held in place as shown in Figure 6C. Be certain you have the BA106/BA119 DuraTap Sieve Cover (30/30a) situated so the dimple in the center can receive the cork or rubber plug as shown is Figure 6A. If the cover is upside-down, the sieves will not be properly held in place and the BA103 Hammer Arm (1) will fall on metal rather than the plug; causing the “sloshing” of the sieves in the assembly and Figure 6B the very noisy tapping.

My DuraTap is making a slapping noise and the oscillation displacement seem to be off. What is happening?

The BA105 Stationary Block (48) is manufactured out of a bronze alloy so that if any wear from heavy or extended use does occur, this block will wear out before the more expensive DA201 Lower Carriage Plate (21) is damaged. If this part becomes worn, the oscillations may change and a slapping noise will be heard.

- Unplug the DuraTap from the power source.

- Turn the unit over and wear on the BA105 Stationary Block (48) may be found.

- Replace the BA105 Stationary Block (48) before damage to the DA201 Lower Carriage Plate (21) occurs.

- Routine greasing of the BA105 Stationary Block (48) will ensure long life. See question 2 for locations of grease fittings.

I want to convert my 8” DuraTap to work with 12” sieves. Can I do that?

Conversion Kits are available for users who want to convert their existing unit to accept either 8” or 12” sieves. No need to incur the expense of another shaker. Simply unscrew 4 bolts and loosen 2 hex nuts.

- PA8 – converts your 12” unit to accept 8” sieves.

- PA12 – converts your 8” unit to accept 12” sieves.

Can the direction of the motor be changed?

No. WARNING: Do NOT attempt to change the direction of the motor. Doing so will cause damage to the DuraTap and will void the warranty.

What is the grade of stainless steel used in the manufacture of Advantech’s test sieves?

- ASTM #8 and coarser sieves use a 304 grade wire cloth

- ASTM #10 and finer use a 316 grade.

- Stainless steel frames are manufactured with 304 grade stainless steel.

What is the warranty on the DuraTap?

The DuraTap carries a one year limited warranty against defective material and workmanship.

What is an extended rim (midstack) pan? Do I need this for my test?

An extended rim pan is manufactured with a skirt around the bottom so it can be received by a sieve below it. This will allow the user to run multiple samples in one stack. The extended rim pan can be inserted mid-stack to collect fines of sample one and the bottom pan will collect fines from sample two.

Does Advantech have a repair facility nearby?

Advantech is pleased to offer telephone repair support for DuraTaps. Contact a member of our Tech Support Team at 262-786-1600. Alternatively, machines may be sent in to our location in New Berlin, WI for extensive repair or refurbishing. Contact us for information on how to prepare your machine for receipt and service by our Repair Department.

For further technical support, please contact our Tech Support Team at 262-786-1600 or at sales@advantechmfg.com. We’d be glad to assist.